Download YG-1 Mastercam Tool Database

Custom Mastercam YG-1 Tool Database

Discover the Efficiency of CNC Machining with our YG-1 Mastercam Tool Database. Elevate your machining projects with our comprehensive and user-friendly tool solutions.

YG1 + Mastercam Features and Benefits

With custom Mastercam setup sheets the CNC Experience precision and versatility with our YG-1 Tool Database. Designed for Mastercam users, this database offers a wide range of YG-1 tools, enhancing your CNC machining with accuracy and efficiency. Save time and improve productivity with easy-to-navigate features and up-to-date tool data.

Reduce Setup Time and Free Up Programming Department

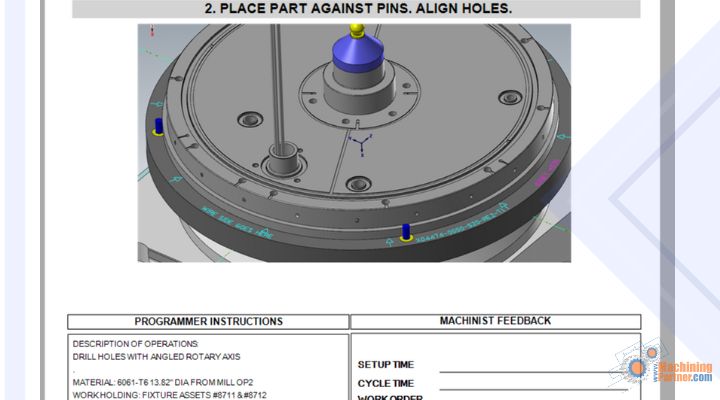

Auto Generate Critical Setup Info. With these custom Mastercam setup sheets the CNC Programmer creates accurate tooling information, displays feeds/speeds, toolpath sequence, coolant information, fixturing information and more. Our custom Mastercam setup sheets are designed to be user-friendly and easy to understand, providing clear and concise instructions to setup machinist so CNC Programmers significantly reduce time wasted with excel spreadsheets, word docs, manually entering data, tooling info, fixturing and setup instructions.

The result is a significant reduction in the time and effort required to create programs, freeing up valuable time for your programmers to focus on more important tasks. Improve communication and collaboration with the setup team and reduce confusion and increasing the efficiency of your operations.

Maximize Efficiency, Minimize Costs: Discover the Unmatched Value of YG-1 Tools with Mastercam Integration

Accurate tooling information

Custom Mastercam setup sheets can help to ensure that the correct tooling is used for each machining operation. This can help to prevent errors and damage to the tools and the workpiece.

Clear and concise instructions

Custom Mastercam setup sheets can provide clear and concise instructions for the setup machinist. This can help to reduce the time and effort required to set up the machine, and it can also help to prevent errors.

Reduced time wasted

Custom Mastercam setup sheets can help to reduce the time wasted by CNC programmers. This is because the sheets can automatically generate much of the information that would otherwise need to be manually entered.

Free up valuable time

Custom Mastercam setup sheets can free up valuable time for CNC programmers. This is because they can spend less time creating and managing setup sheets, and they can focus on more important tasks, such as programming new parts.

Improved communication

Custom Mastercam setup sheets can help to improve communication between CNC programmers and setup machinists. This is because the sheets can provide a common language for discussing CNC machining operations.

Increased productivity

Custom Mastercam setup sheets can help to increase productivity by reducing the time and errors associated with CNC machining operations.

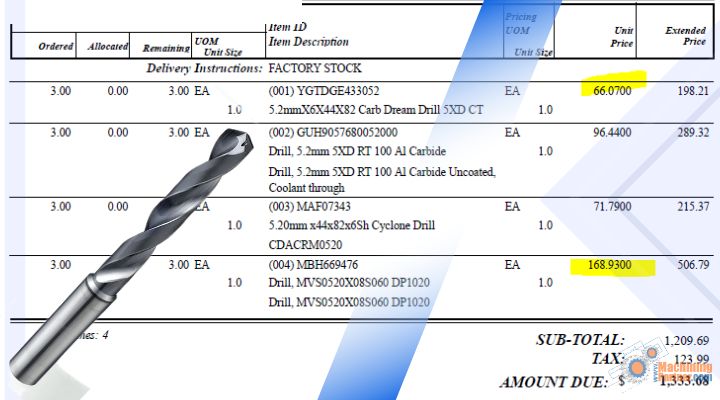

YG-1 Tools Are Affordable

YG-1 Tools offer an exceptional blend of quality and affordability, a crucial factor for manufacturers looking to reduce their consumable costs, particularly in cutting tools. For instance, while brands like Mitsubishi, M.A.Ford, and Guhring offer drills ranging from $71.79 to $168.93, YG-1 provides its high-quality Dream Drill carbide DLC for only $66.70. This represents not just savings, but a smart investment in durable, efficient tools. Pairing YG-1’s cost-effective solutions with Mastercam’s seamless integration enhances overall manufacturing efficiency and reduces operational costs

Add Programmer’s Written and Visual Instruction – Instant Feedback From Machinists

Tools have evolved remarkably, offering an impressive balance of high quality and affordability..

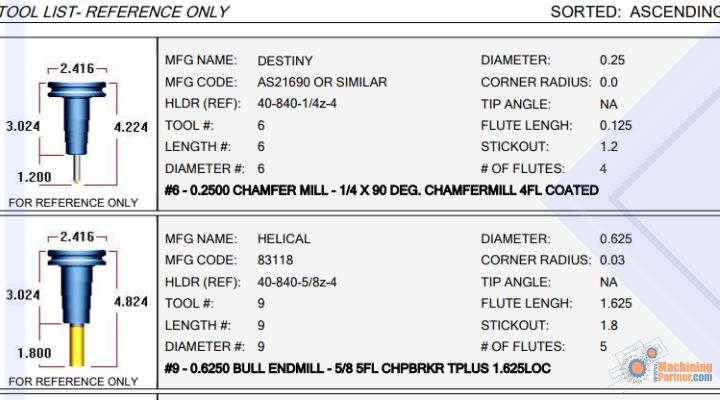

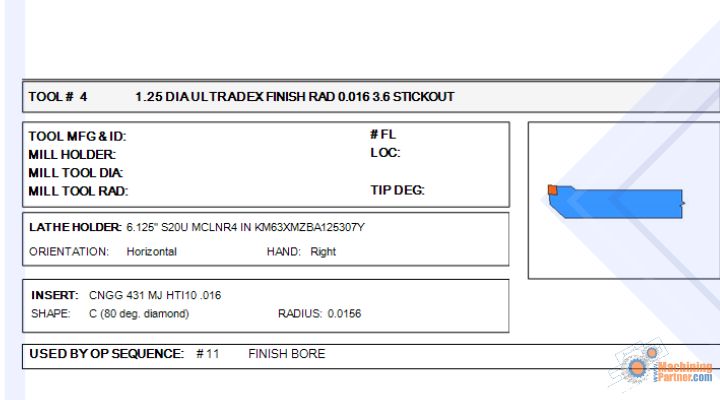

Auto Generated Tool and Holder Information

Our custom setup sheets automatically generate detailed cutting tool data for each operation like tool names, diameters, lengths of cut, radii, manufacturer part numbers, and holder part numbers. Visual representations of the tools and holders are also included for quick identification.

Having this precise tooling information available ensures machinists select the correct assemblies intended by programmers and match specifications in the programming model. This guarantees optimal cutting performance.

With the automated tool details and graphics integrated into the chronological setup sheets, handoff from programming to production is seamless. Machinists will appreciate the clear specifications when proving out programs and setting up jobs.

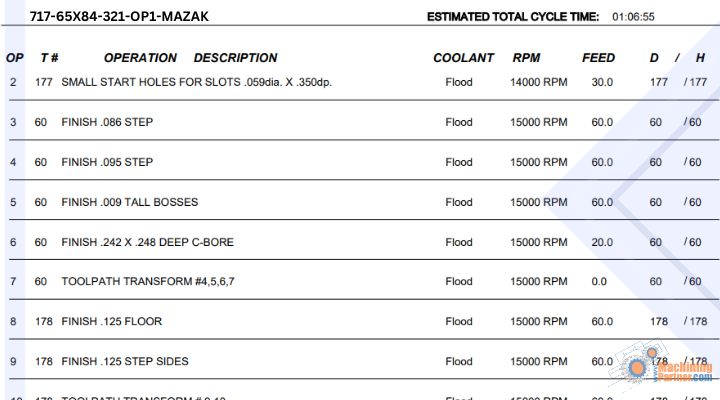

Auto Generated Toolpath Information

With just two clicks, programmers can generate detailed setup sheets that outline the entire machining process in easy-to-follow chronological order. This allows machinists to understand the sequences and operations exactly as envisioned by the programmer.

These setup sheets include vital information for each step such as: Toolpath descriptions, Coolant types, RPM and feed rates, Tool offsets, Estimated cycle times.

This chronological overview is incredibly valuable for proving out programs. It allows machinists and programmers to instantly pinpoint specifics like “sequence #5” to isolate any issues or improvements, instead of wasting time hunting through code.

Works For Vertical, Turning, Horizontal, Mill Turn, 5 Axis and more

Our custom setup sheets are tailored to your specific needs and are loaded with features and benefits that will help you increase productivity and customize your Mastercam software.

Any Machine, if it can be done, we’ll create custom setup sheets for you and custom Mastercam posts. Mastercam 2018 and higher, tested up to Mastercam 2024. Using Mastercam’s migration wizard you may upgrade the files for newer versions. Also offering, Esprit, Surfcam, Siemens NX, Creo, Solidcam, Edgecam, Hypermill, GibbsCam. Contact Us.

help to avoid misunderstandings and errors.

Effortless Installation in Just Minutes

Installing our custom Mastercam setup sheets takes only minutes and requires no technical expertise. Simply download the provided zipped folder after purchase, back up any existing files as a precaution, and extract the folder contents. Then follow our instructions to copy key files into specific Mastercam locations. That’s it! Our self-contained setup introduces no risk and will not alter your existing Mastercam installation.

1 - download files

2 - extract files

3 - paste files

Extract Mastercam Data for Any Setup System

Our custom setup sheets provide value even for companies that program in Mastercam but do not use it for generating setup books. Programmers can use our templates to swiftly compile key data like tool details, operations sequences, and graphics. This information can be transferred to company standard templates and excel setup documents, avoiding tedious and error-prone manual entry. Whether your shop uses Mastercam for setup books or other solutions, our professionally formatted sheets help programmers instantly populate critical tooling and machining data to enhance workflow and reduce mistakes.

As an example, manually entering 20 tools into a spreadsheet at 2 minutes per tool requires at least 40 minutes. Retrieving the same information from our Mastercam sheets takes only 3-5 seconds total, saving over 35 minutes.

Avoid hand typing tool parameters by leveraging our templates to rapidly extract and transfer key data to your existing setup templates, avoiding major time waste and mistakes.

Auto Generated Toolpath Information

With just two clicks, programmers can generate detailed setup sheets that outline the entire machining process in easy-to-follow chronological order. This allows machinists to understand the sequences and operations exactly as envisioned by the programmer.

These setup sheets include vital information for each step such as: Toolpath descriptions, Coolant types, RPM and feed rates, Tool offsets, Estimated cycle times.

This chronological overview is incredibly valuable for proving out programs. It allows machinists and programmers to instantly pinpoint specifics like “sequence #5” to isolate any issues or improvements, instead of wasting time hunting through code.

Get Your Custom Mastercam Setup Sheets Now

Designed by machinists for machinists, the setup sheets populate critical tooling data, operations sequences, and instructions in seconds.

- Instant Access

- Quick Installation

- 14 days Money back Guarantee

- Free minor customizations

Stop wasting hours on manual setup documentation. Get the Mastercam custom setup sheets used by top shops worldwide to accelerate programming and machining today!

We also offer full 3D CNC machine Models from leading machine builders.

Doosan CNC machine stl CAD 3D model, Haas CNC machine stl CAD 3D model, Mazak CNC machine stl CAD 3D model, Makino CNC machine stl CAD 3D model, Mori Seiki CNC machine stl CAD 3D model, Okuma CNC machine stl CAD 3D model, Hitachi Seiki CNC machine stl CAD 3D model, Matsura CNC machine stl CAD 3D , model, OKK CNC machine stl CAD 3D model, DMG MORI CNC machine stl CAD 3D model, Hurco CNC machine stl CAD 3D model, KUKA CNC machine stl CAD 3D model, Nigata CNC machine stl CAD 3D model, Mazak Integrex, Mazak J300, Nakamura CNC machine stl CAD 3D model, Grob CNC machine stl CAD 3D model, Brother CNC machine stl CAD 3D model, Mastercam Custom Setup Sheets you may be interested in custom cnc programming services