Mechanical Design & Drafting Services

Hire On-Demand Drafters and Engineers

Leverage our engineering expertise to expedite your manufacturing process from concept to finished product.

Expertise Across CAD Platforms and Manufacturing Processes

Our mechanical design engineers and CAD drafters combine expertise across major software platforms like SolidWorks and AutoCAD with deep knowledge of manufacturing processes like machining, fabrication, and assembly. This enables us to seamlessly deliver tailored CAD models, drawings, renderings, and other design assets optimized for your specific industry and proprietary processes. Whether you need fixtures, machinery, or product enclosures, we become an extension of your team by leveraging our multifaceted experience in both engineering software and real-world manufacturing demands.

Drafting and 3D product design services include:

- Creating drawings, 2D, 3D CAD modeling from conceptual sketches

- 2D drawings, in-process instructions for fabrication and assembly

- Fixture and tooling design including fasteners, jigs, machine tables, tombstones etc

- Design of material handling equipment including conveyors, cranes, hoist etc

- Manufacturability analysis and design specifications

- Stress analysis for furnaces, storage tanks, pressure vessels, piping systems

- Model and drafting file format conversion

- and more

On-Demand Engineering Design Services Saves You Time and Money

Fast-Track from Concept to Manufacturing

Our on-demand engineering team provides comprehensive design services to quickly turn your concepts into manufactured products—without the overhead of in-house teams.

Validate Innovations with Simulations

Leveraging our broad expertise, we convert sketches to 3D CAD models to test concepts through engineering simulations before investing in prototypes.

Accelerate Time-to-Market

Our contract engineering services rapidly develop CAD prototypes to shorten your design process and speed time-to-market. We eliminate iterative loops to finalize your product faster.

Drive Savings Through Design Optimization

Our engineering team identifies cost-saving optimizations in materials, manufacturing steps, assembly time, and more—making your product more profitable and competitive.

Mistake-Free Quality Built-In

Flawless drafting is ensured through our strict multi-stage quality framework. Our rigorous process provides mistake-free designs to maximize manufacturing success.

Custom Fixturing and Tooling Design

Our mechanical engineers have extensive experience designing and optimizing custom fixtures, jigs, machine tables, and other tooling to enhance manufacturability.

Let Our Experts Handle Your Next Machine Design Project

Contact our on-demand engineering services today to discuss your specific machine design and manufacturing needs. Let’s find solutions to streamline your development process from start to finish.

Technical Manufacturing Drawings for Seamless Production

Also known as working drawings, production or manufacturing drawings contain all the critical information needed to fully manufacture and fabricate parts and final assemblies. A complete set of drawings enables clear communication between engineering, quality control, and shop floor technicians to coordinate smooth manufacturing.

Comprehensive Part and Component Drawings

Detailed part drawings provide machinists and technicians with specifics to fabricate individual components. Our drafting services outline material specifications, linear and angular dimensions with associated tolerances, geometric tolerances, surface finish callouts, coatings, treatments, and other critical notes needed for manufacturing success.

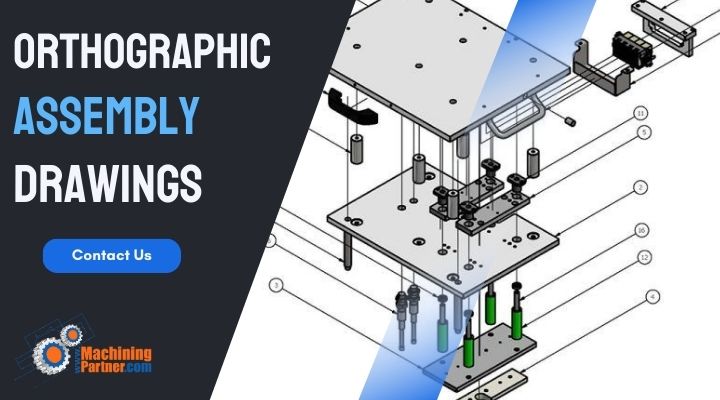

Communicating Assembly Instruction

For assemblies, drawings clearly illustrate sub-components, hardware, bill of materials, and views showing how parts fit together. We include isometrics, orthographics, exploded views, and full assembly drawings with essential notes. Communicating assembly sequences while adhering to industry standards ensures optimal manufacturability.

Let Our Experts Handle Your Next Machine Design Project

Contact our on-demand engineering services today to discuss your specific machine design and manufacturing needs. Let’s find solutions to streamline your development process from start to finish.