Here is a potential excerpt from the robotics startups article:

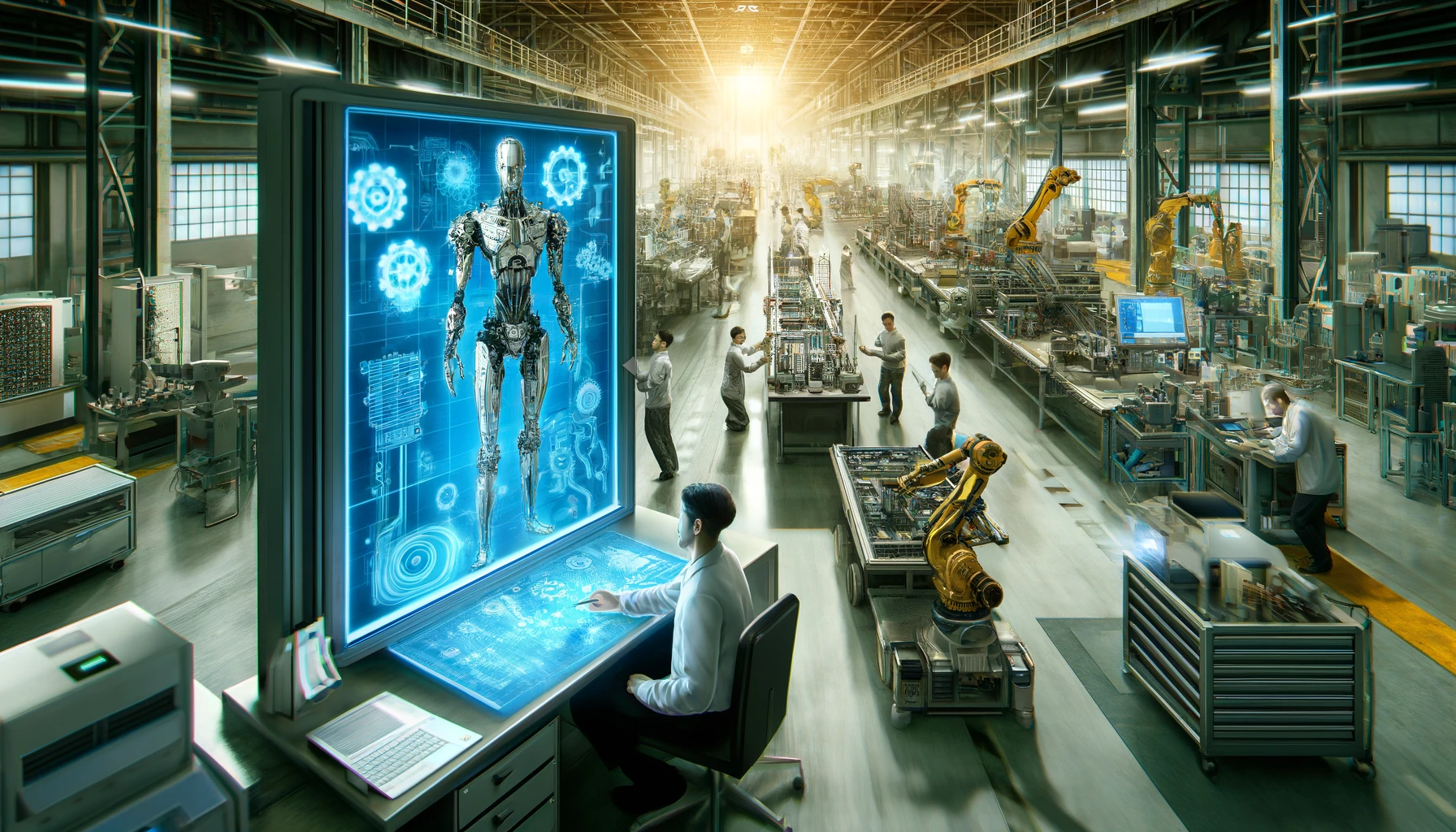

Robotics startups have immense potential to transform lives through groundbreaking innovations. But the road from prototype to deployed product presents immense hurdles across funding, engineering, design, manufacturing, regulations, and business operations.

This comprehensive guide examines the 11 most common challenges robotics entrepreneurs encounter and proven solutions to overcome each through strategic partnerships, rigorous processes, and perseverance.

Some of the biggest obstacles include:

Designing for manufacturability, lifecycle, and reliability when transitioning from prototype to production. This requires extensive redesign using DFMA principles.

Navigating strict regulations and certifications like ISO, FCC, UL, EMC, and various safety standards. Meeting requirements adds great complexity.

Managing interdependent hardware and software development. Keeping tightly coupled subsystems in sync is immensely challenging and bug-prone.

Integrating diverse cutting-edge technologies like sensors, motors, batteries, AI, and new materials into cohesive products. Systems complexity is immense.

Securing sufficient startup funding and capital. Developing robots necessitates substantial long-term investment unappealing to most investors.

By leveraging strategic partnerships, following rigorous development processes, and persevering through hurdles, robotics startups can turn innovations into reality. This guide shares proven advice to accelerate success.