Invert-A-Bolt™ (Invertabolt) Fasteners Revolutionize Manufacturing Practices

Invertabolt fasteners, also known as Invert-A-Bolt™, are a game-changing solution for lean manufacturing practices in the workplace. These flush-mounted, captive fasteners eliminate the need for dedicated fixturing, reducing costs for tool design, manufacture, maintenance, and storage. Invertabolt fasteners also standardize tooling and work practices, leading to increased efficiency and productivity.

Invertabolt fasteners, also known as Invert-A-Bolt™, are a game-changing solution for lean manufacturing practices in the workplace. These flush-mounted, captive fasteners eliminate the need for dedicated fixturing, reducing costs for tool design, manufacture, maintenance, and storage. Invertabolt fasteners also standardize tooling and work practices, leading to increased efficiency and productivity.

Zero Point Systems vs. Invertabolt Fasteners

Lang and Schunk zero point systems offer higher precision and repeatability compared to Invertabolt fasteners. These systems are designed for automated production environments where precise, consistent positioning is critical, such as in machining, assembly, and inspection.

Lang and Schunk zero point systems offer higher precision and repeatability compared to Invertabolt fasteners. These systems are designed for automated production environments where precise, consistent positioning is critical, such as in machining, assembly, and inspection.

Invertabolt fasteners, on the other hand, are typically used in a picture-frame setup, where they are inserted into tab locations to hold down the workpiece while simultaneously locating it at the bushed hole locations in the fixture. This setup is ideal for many parts, as it does not require hard location against datums.

Advantages of Using Invertabolt Fasteners

Invertabolt fasteners bring numerous benefits to manufacturing processes:

- Versatility: Invertabolt fasteners can serve as quick-change bolts, eliminating the need to grind them down to size or stop the machine to change clamps. They are easy to install and use, and can be clamped and unclamped quickly.

- Improved efficiency: Invertabolt fasteners enhance high-speed horizontal machining by reducing the risk of tooling clashes. Their small footprint and “base-up” holding power pose little risk to high-speed spindles. Invertabolt fasteners also eliminate vibration in the setup, enabling optimal feed rates and improving the efficiency of the machine tool.

- Cost savings: Invertabolt fasteners eliminate the need for dedicated fixturing and reduce costs for tool design, manufacture, maintenance, and storage, providing long-term cost savings. They are a cost-effective solution for many manufacturing applications.

Installation and Use

To use Invertabolt fasteners, screw the larger outer (housing) diameter into the fixture plate until it is flush with the surface. Then, screw the smaller (stud) diameter in and out of the larger housing diameter. When in use, the smaller stud diameter screws into the component material to hold it in place during machining. When not in use, the smaller stud diameter fully retracts into the larger housing diameter, allowing easy access to the workpiece.

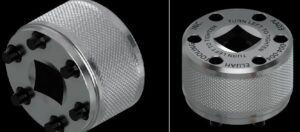

Inverta bolt fasteners require the use of specialized insertion tools in order to be installed. These tools are pricey, such as the AA02 type fasteners, have replaceable, screw-in drive pins, either 3-hole, 4-hole, or 6-hole by retracting the unused pin(s) to match the number of holes on top that are used to secure the fastener into its receiver. These drive pins are available in stainless steel with knurled O.D.

Inverta bolt fasteners require the use of specialized insertion tools in order to be installed. These tools are pricey, such as the AA02 type fasteners, have replaceable, screw-in drive pins, either 3-hole, 4-hole, or 6-hole by retracting the unused pin(s) to match the number of holes on top that are used to secure the fastener into its receiver. These drive pins are available in stainless steel with knurled O.D.

The AA03 and AA06 type fasteners are also specialized insertion tools that can be used with a variety of Invertabolt fasteners, including 3-hole, 4-hole, and 6-hole versions. These tools also have replaceable, screw-in drive pins that are used to secure the fastener into its receiver.

It is important to use the correct insertion tool for the specific type of Inverta bolt fastener being used, in order to ensure proper installation and secure holding power.

About Invertabolt and Elijah Tooling

Invertabolt fasteners are designed and patented by Elijah Tooling, based in Denton, TX. These fasteners offer versatility, ease of use, and improved efficiency and productivity. They are a valuable tool for many manufacturing applications and streamline the production process by eliminating dedicated fixturing and reducing the costs associated with tool design, manufacture, maintenance, and storage. Visit Elijah Tooling Denton, TX