Kurt Vise Jaw Dimensions: Choosing the Right Vise for Your Needs

Kurt vise jaw dimensions are an important consideration when selecting a vise for your workshop or job site. A vise is a mechanical device that holds a workpiece securely in place, allowing you to work on it with greater precision and control. There are many different types of vises available, each with its own set of features and capabilities. Understanding the various jaw dimensions of a Kurt vise can help you choose the right one for your needs.

Uses of a Vise

Uses of a Vise

One of the main uses of a vise is to hold a workpiece steady while it is being machined or worked on in some other way. This can include cutting, grinding, drilling, or sanding. A vise with adjustable jaws allows you to accommodate different sizes and shapes of workpieces, making it a versatile tool for any workshop.

Features of Kurt Vises

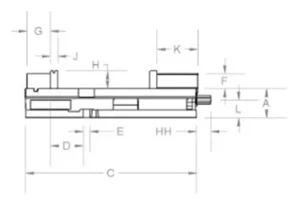

Kurt vises are known for their high-quality construction and precision engineering. These vises are made with close tolerances and smooth-moving jaws, making them ideal for fine work and precise machining. The jaw dimensions of a Kurt vise are an important factor in its overall performance and versatility.

Factors to Consider

There are several factors to consider when choosing the jaw dimensions of a Kurt vise. The first is the size of the workpiece you will be working on. If you are machining small parts, you may need a vise with narrow jaws to hold them securely. On the other hand, if you are working on larger parts, you may need a vise with wider jaws to accommodate them.

Another factor to consider is the type of work you will be doing. If you need to apply a lot of clamping pressure to hold your workpiece in place, you may need a vise with deeper jaws to provide more surface area for clamping. On the other hand, if you only need a light touch to hold your workpiece, you may be able to get by with shallower jaws.

Types of Kurt Vises

There are many different types of Kurt vises available, each with its own set of jaw dimensions. Some of the most common include:

- Kurt D-series vises: These vises have a maximum jaw opening of 4.5 inches and a jaw width of 3.5 inches. They are ideal for machining small parts and have a maximum clamping pressure of 7,500 lbs.

- Kurt DX-series vises: These vises have a maximum jaw opening of 7.5 inches and a jaw width of 6 inches. They are suitable for machining larger parts and have a maximum clamping pressure of 10,000 lbs.

- Kurt GX-series vises: These vises have a maximum jaw opening of 9 inches and a jaw width of 7.5 inches. They are designed for heavy-duty machining and have a maximum clamping pressure of 12,000 lbs.

In addition to Kurt vises, there are many other brands of vises available that offer a range of jaw dimensions. Some of the most popular include Wilton, Yost, and Bessey. When choosing a vise, it is important to consider the size and type of work you will be doing, as well as your budget and the overall quality of the vise.

Conclusion

In conclusion, the jaw dimensions of a Kurt vise are an important consideration when selecting a vise for your workshop. Understanding the different sizes and capabilities of the various Kurt vise models can help you choose the right one for your needs. Whether you are machining small parts or working on larger projects, a high-quality vise with the right jaw dimensions can make all the difference in your work.

For over 50 years, Kurt has been a leader in the design, engineering, and manufacturing of high-quality and high-performance workholding solutions. Their product line includes single station vises, towers, tombstones, modular vises, and 5-axis options, all of which can be integrated into new or existing automated cells and gaging systems. No matter what your application, Kurt makes it easy to find the right workholding product for your needs. Visit Kurt