Vericut Software: The Ultimate Review of CNC Machining Simulation

If you use CNC machines for manufacturing, you need to know about VERICUT software. VERICUT is the leading solution for simulating, verifying, and optimizing NC machining programs on a computer before ever hitting the shop floor.

Word of caution! No matter how great your simulation program is, there is always “Bob” who forgets to remove clamps!

This comprehensive VERICUT review will cover everything you need to know to take your CNC processes to the next level.

What Does VERICUT Do?

In simple terms, VERICUT lets manufacturers simulate CNC machining on a virtual machine instead of wasting time and materials physically proving out programs.

It checks for:

- Errors in NC code that could break tools or crash machines when cutting.

- Collisions against fixtures, clamps, workpieces and any machine components.

- Optimizes programs for faster cycle times and longer tool life.

VERICUT runs the EXACT same G-code and logic as the CNC control – no approximations. So you know your programs run flawlessly when you hit cycle start for real. Many other simulation software run actual NCI code not NC code which is not the same as the actual machine will run and may miss critical toolpaths and possible collisions.

CG Tech claims cutting metal the first time with confidence reduces scrap, saves production time, and improves part quality. VERICUT pays for itself extremely fast. If you have been in machining any amount of time you will know there is no perfect program on the first go, while most critical issues can be reduced like spindle crash you can never account for “Bob” forgetting” to remove clamps or listening, feeling and checking chips to adjust feeds and speeds.

Benefits of CNC Machining Simulation With VERICUT:

- Avoid disastrous machine crashes from program mistakes

- Reduce scrapped parts by finding NC program errors virtually

- Speed up new product introductions and machine setups

- Optimize machining efficiency and toolpaths

- Train programmers without wasting materials

- Document digitally proven programs for quality records

Many leading manufacturers like Boeing, GM, and Intel trust VERICUT for its power, flexibility, and return on investment. Contact us to discuss your specific CNC programming challenges.

VERICUT Capabilities

VERICUT handles a wider range of manufacturing than any other simulation software:

CNC Machine Simulation

- Models your exact machines – lathes, mills, robots, fiber placement, etc.

- Checks for crashes and near-misses during simulation.

- Confirms new programs work properly before live cutting.

NC Program Verification

- Finds mistakes like bad coordinates or toolpaths.

- Measures features and detects errors against CAD models.

- Captures digital proof that parts match specifications.

Multi-Axis Machining

- Handles complex 3-5 axis mills, mill-turns, multi-spindle machines, and articulated robots.

- Verifies head positioning, clearance, and synchronization.

- Great for aerospace and medical part programming.

Feed Rate Optimization

- Automatically optimizes programs for faster cycles and better tool life.

- Maintains ideal chip loads and material removal rates.

- Handles roughing, finishing, hard and soft materials.

Composites Programming

- Models composite layup paths for fiber placement and tape laying.

- Checks steering, gaps, overlaps, layer offsets, and collisions.

Drilling and Fastening

- Simulates automated drilling and fastening of large assemblies.

- Verifies right tools used in correct sequence and positions.

- Great for aircraft and automotive manufacturing.

Automation Interfaces

- Automates CAD, CAM, and tooling data imports.

- Eliminates rework by integrating with engineering processes.

- Open architecture fits into any production environment.

This super quick overview just scratches the surface of VERICUT’s deep capabilities specialized for CNC machining processes. Get in touch to have our experts dive deeper into how VERICUT can help your specific parts and programming.

Request a quote to discuss licensing options and pricing for your shop. We offer significant discounts not advertised online.

Who Uses VERICUT?

Nearly every industry leverages VERICUT’s power for CNC optimization and mistake-proofing:

- Aerospace – Boeing, Airbus, GE, Rolls Royce, Northrop Grumman

- Automotive – Toyota, GM, Ford, Honda, VW, Mercedes, Nissan

- Medical – DePuy, Zimmer Biomet, Stryker

- Mold & Die – Kennametal, Hasco, Roeders, Meusburger

- Energy & Transportation – Siemens, Alstom, Baker Hughes, Caterpillar

- Consumer Products – P&G, Energizer, Newell Brands

- Job Shops – Gen Swiss, MFD, Pacific Swiss

- And many more! Over 10,000 users globally trust VERICUT.

Leading manufacturing companies, small shops, technical universities, and NC programmers worldwide rely on VERICUT for optimizing CNC machining efficiency while reducing mistakes.

See VERICUT customer success stories.

VERICUT Tips and Tricks

With decades of experience applying VERICUT, we’ve compiled some pro tips and tricks for getting the most from your investment:

- Take advantage of free VERICUT training to ramp up programmers fast.

- Work with CGTech experts on custom machine configurations matching your exact shop equipment.

- Automate the NC program handoff from your CAM system to VERICUT to save time.

- Let CGTech optimize your programs rather than doing it manually.

- Use VERICUT’s custom reporting tools to output digital quality records.

- Modify VERICUT’s default NC program processes to match your workflow.

- Script routines in Python for specialized automation.

The CGTech support team is always available to help optimize your VERICUT experience. Reach out with any questions!

VERICUT Pricing and Licensing

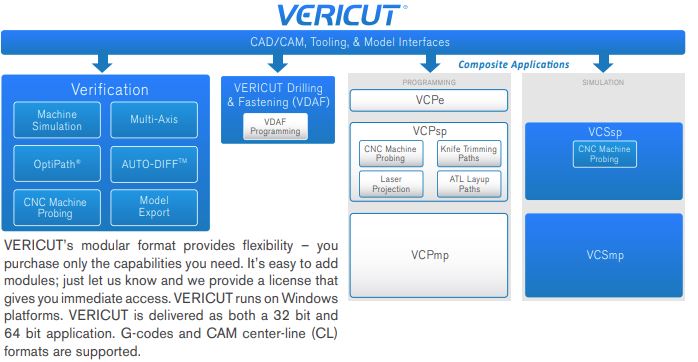

VERICUT is licensed by number of concurrent users and the specific modules needed for your applications.

Price varies based on factors like:

- Number of seats

- Simulation capabilities required (basic, multi-axis, composites, etc.)

- Additional optimization, CAD interfaces, reporting modules.

Supposedly A basic 3-axis package starts around $7,500 for a single license. However, in reality it’s about $25,000, Read more about Vericut Price.

However, exact VERICUT pricing is tailored to your specific shop and applications. Contact us for exclusive discounts for Vericut and possible alternatives! Vericut experts supporting thousands globally, we offer significant discounts unavailable through typical website pricing or resellers.

Whether you are budget-limited or require advanced multi-axis machining validation, we make VERICUT affordable. Request a quote!

Conclusion: Should You Invest in VERICUT?

For any manufacturer using CNC machines, VERICUT is an easy win for optimizing efficiency, quality, and productivity.

The cost savings from scrap reduction, faster setups, and program optimization far outweigh the software investment.

Top companies trust VERICUT for good reason – it delivers a fast ROI while taking the headaches out of programming complex parts.

Ready to discuss how VERICUT can help your specific parts, machines, and technical challenges? Get in touch and request a quote to talk with our team of machining experts.

We offer personalized pricing and stand behind VERICUT with world-class support to ensure you get the maximum results from simulation.

Now is the time to finally solve your CNC programming headaches and take your manufacturing to the next level with VERICUT.