Enhancing Manufacturing Efficiency with Vericut: Unlocking Optimal Savings

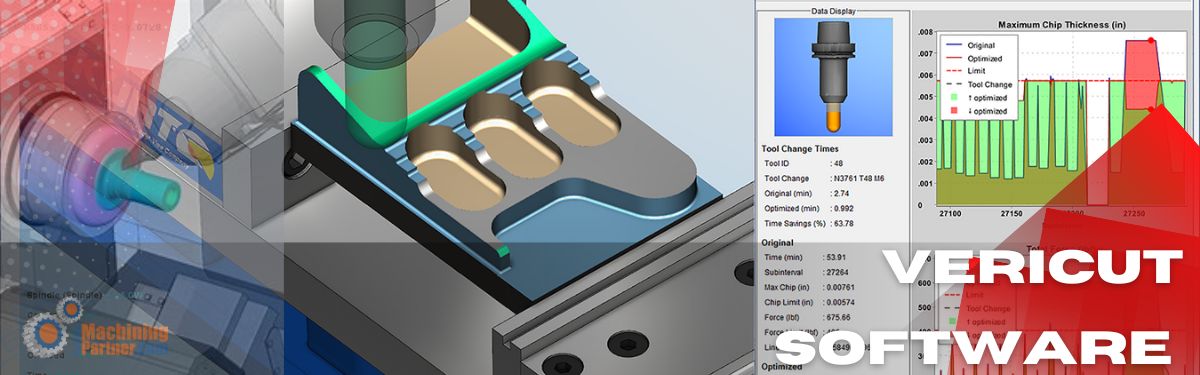

In the dynamic world of manufacturing, precision, efficiency, and cost savings are paramount to staying competitive. As a machinist or manufacturer, you understand the importance of streamlining your production processes while ensuring the highest quality standards. This is where Vericut comes into play – the revolutionary CNC simulation and optimization software that has been transforming the industry.

What is Vericut?

Vericut is a cutting-edge software solution developed by CGTech, renowned for its excellence in the realm of CNC machining and simulation. It is specifically designed to address the challenges faced by manufacturers and machinists, providing them with the tools to simulate, verify, and optimize their machining operations. With Vericut, you can ensure that your CNC programs run efficiently and safely, eliminating costly errors and minimizing downtime.

Why Choose Vericut?

- Unmatched Accuracy: Vericut’s collision detection capabilities enable you to visualize toolpath motion and identify potential collisions, ensuring that your machining process is precise and error-free.

- Time and Cost Savings: By simulating and optimizing your CNC programs, Vericut helps reduce material waste, tool wear, and machine downtime, resulting in significant cost savings.

- Streamlined Workflow: Vericut’s user-friendly interface and intuitive features streamline your manufacturing workflow, allowing you to focus on innovation and productivity.

- Mastercam Integration: Vericut seamlessly integrates with Mastercam, a leading CAM software, enhancing your machining capabilities and enabling smoother collaboration between design and manufacturing teams.

Exploring Vericut’s Features

- Collision Detection: Vericut’s sophisticated algorithms detect potential collisions between cutting tools, fixtures, and machine components, preventing costly accidents during actual machining.

- Material Removal Simulation: Visualize material removal during machining to optimize toolpaths, minimizing cycle times and ensuring optimal chip evacuation.

- Toolpath Optimization: Vericut’s optimization features refine toolpaths to achieve the highest level of efficiency and surface finish, maximizing the potential of your CNC machine.

- Reverse Engineering: Vericut facilitates reverse engineering processes by transforming scanned data into precision components and aiding in the creation of CAD models. Easier CMM Programming.

- GD&T Verification: Verify Geometric Dimensioning and Tolerancing (GD&T) on your machined parts, ensuring they meet the required specifications.

What Users are Saying

Industry professionals have praised Vericut for its game-changing impact on manufacturing efficiency and quality:

“Vericut has been a game-changer for our company. It has eliminated costly errors and enabled us to optimize our machining processes, resulting in significant time and cost savings.” – John, Manufacturing Manager

“The integration with Mastercam is seamless. Vericut’s simulation capabilities have given us the confidence to take on complex projects with ease, knowing that we can identify and resolve any issues before they occur.” – Andy, CNC Programmer

Exclusive Offers and Discounts on Vericut Software

To support manufacturing professionals in their journey towards precision and productivity, Vericut offers exclusive discounts and packages. Inquire today to avail of special deals tailored to your business needs.

Incredible Savings on VeriCut

Vericut is more than just software; it is a powerful ally in your quest for manufacturing excellence. By incorporating Vericut into your workflow, you can unlock efficiency, optimize processes, and achieve substantial cost savings. Take the next step towards precision manufacturing and inquire about exclusive offers and check Vericut Price today.

Experience the Vericut advantage – Empowering manufacturers for a better tomorrow. Vericut Training

Optimize CNC Machining With VERICUT Simulation Software

For manufacturers using computer numerical control (CNC) machines, VERICUT software is an invaluable tool for simulating, verifying, and optimizing machining processes. VERICUT helps you avoid costly errors and improve efficiency right from your computer.

Key Features of VERICUT

CNC Machine Simulation

VERICUT simulates your exact CNC machines with a virtual model. It detects potential collisions, near-misses, and overtravel errors during simulation before machining ever takes place.

NC Program Verification

VERICUT verifies NC code and toolpaths, checking for errors that could ruin the part, damage tools, or crash machines. It catches mistakes before you cut metal.

Multi-Axis Machining Support

Beyond basic 3-axis milling, VERICUT handles multi-axis positioning and continuous 5-axis contouring for advanced machining centers.

Feed Rate Optimization

The OptiPath module automatically optimizes feeds and speeds based on changing cut conditions for faster cycle times and extended tool life.

Composite Machining

Special composites modules handle automated fiber placement, tape laying, laser projection, and more for composite part programming and simulation.

Drilling and Fastening

The VERICUT Drilling and Fastening add-on handles programming and simulating automated drilling and riveting machines.

Automation Interfaces

VERICUT integrates with leading CAM systems, tool management software, and other manufacturing applications via open interfaces.

Customization Capabilities

VERICUT can be customized with Python scripting for specialized simulation functionality within your environment.

Key Benefits of Using VERICUT

- Avoid collisions and potential crashes before machining ever takes place.

- Reduce scrapped parts by verifying NC programs for errors.

- Validate new NC programs without wasting production time.

- Improve machining efficiency with optimized cutting feeds and speeds.

- Support advanced machining methods like multi-axis and composites.

- Automate processes by integrating with upstream/downstream software.

- Train new programmers and machinists effectively with no wasted materials.

- Simulate machines, tools, and exact cutting motions before setting up jobs.

VERICUT gives manufacturers unique in-process visibility and tools to simulate CNC machining operations with a virtual machine. This helps you increase efficiency, quality, and productivity for all types of machining.

Learn More About VERICUT

Main keywords: vericut, vericut software, vericut training, cgtech vericut, vericut price, manufacturing efficiency, workflow optimization, savings, exclusive offers, discounts, CNC machining, machine simulation, CNC verification, vericut review